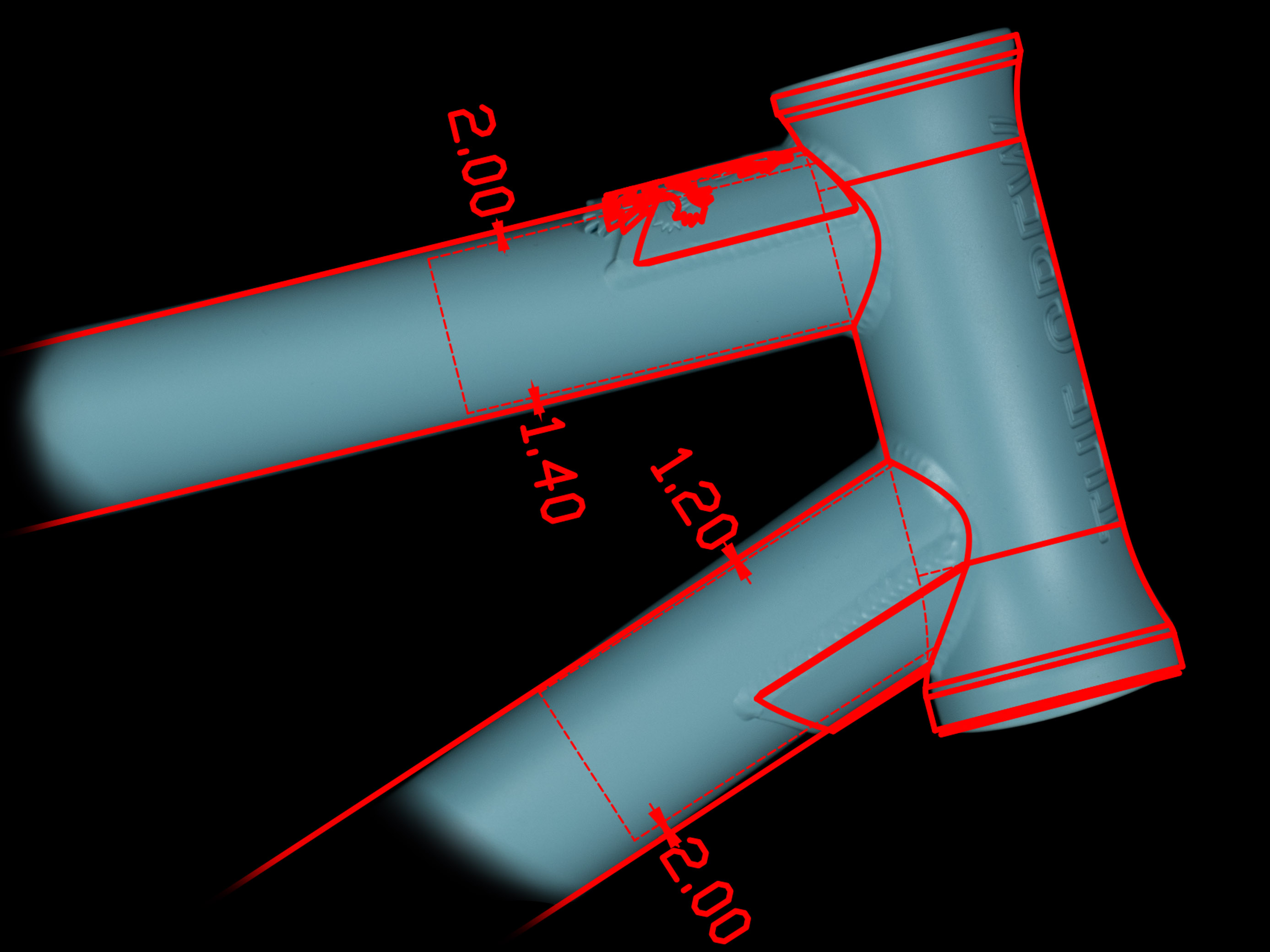

According to statistics, in 60% of cases, the frame breaks around the head tube. This spot is a real stress concentration.

In addition to external gussets on both tubes, we also use branded integrated gussets. This means that tube walls are 66% thicker where the main load is, and thinner where there is no load.

The second weak point in most cases is the spot where the seat stays are welded to the seat tube. It accounts for about 30% of all broken frames.

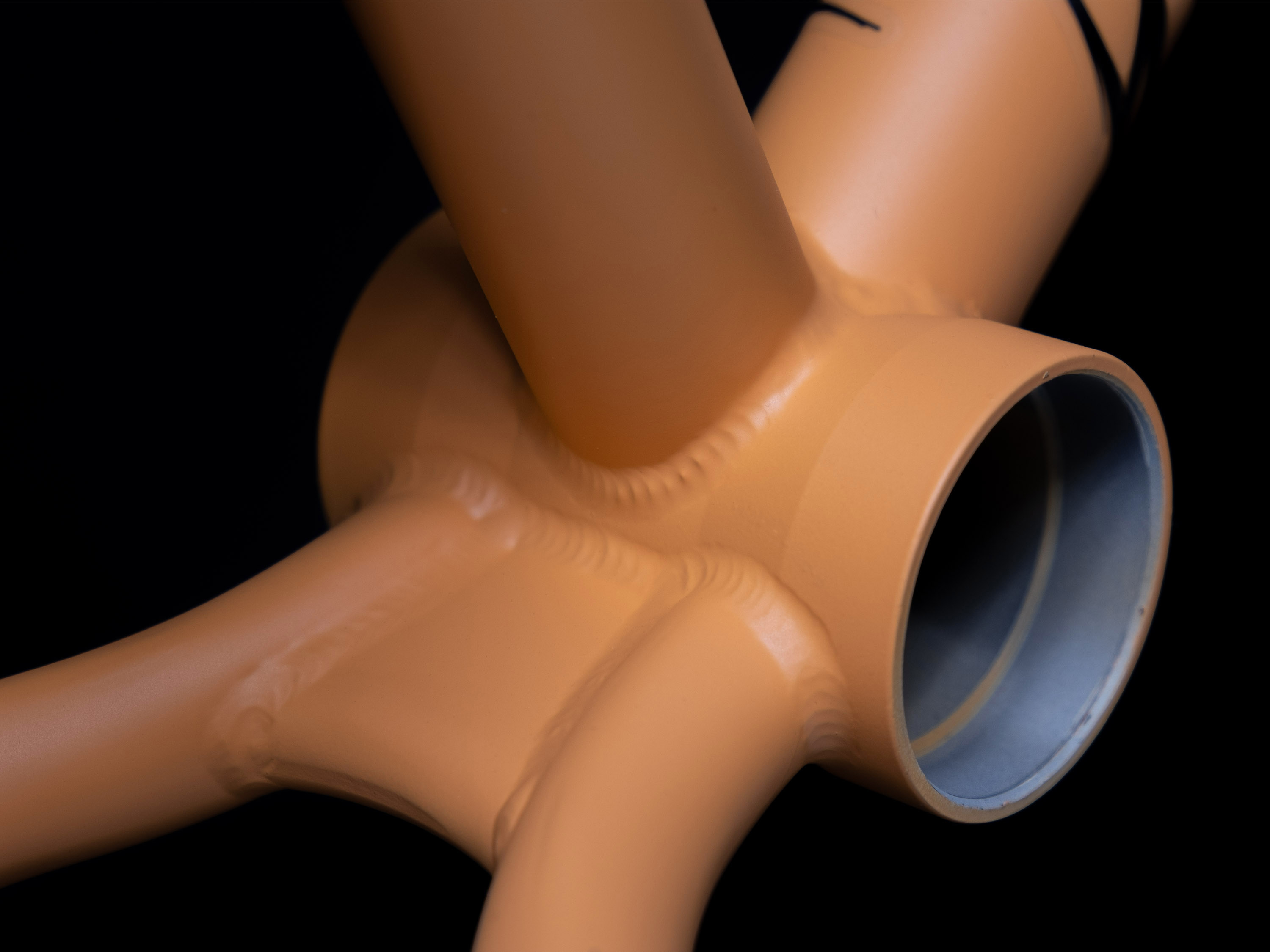

On all our frames, we made an additional gusset between the seat stays, which increases the strength of this spot almost twice. As a result, we have never seen any The Crew Frames break in this spot over the past 5 years

The chain stays break less often, but instead of a standard bridge, we also made our own Wolfbone gusset.

We heat-treated the down tube to prevent dents from unsuccessful grinds.

We made the walls of both tubes of the frame thicker where necessary, and thinner where possible. The walls of the tubes change their thickness up to 3 times - this is called triple butting.

According to statistics, in 60% of cases, the frame breaks around the head tube. This spot is a real stress concentration.

In addition to external gussets on both tubes, we also use branded integrated gussets. This means that tube walls are 66% thicker where the main load is, and thinner where there is no load.

The second weak point in most cases is the spot where the seat stays are welded to the seat tube. It accounts for about 30% of all broken frames.

On all our frames, we made an additional gusset between the seat stays, which increases the strength of this spot almost twice. As a result, we have never seen any The Crew Frames break in this spot over the past 5 years.

The chain stays break less often, but instead of a standard bridge, we also made our own Wolfbone gusset.

We heat-treated the down tube to prevent dents from unsuccessful grinds.

We made the walls of both tubes of the frame thicker where necessary, and thinner where possible. The walls of the tubes change their thickness up to 3 times - this is called triple butting.

Press image to see more photos

Features:

Lifetime warranty since 2020

Japanese SANKO tubes (Crmo 4130)

no brake mounts

heat-treated head tube, BB, dropouts and down tube

inner gussets

gusset between seat stays

colors: matte mint, matt salmon, matt clear raw and matt black

size 20,5″; 20,8″; 21″;

rear end 12,9″;

standover 9,1″;

BB height 11,5″;

headtube angle 75,5º;

seattube angle 71º;

MID BB

вес 2300грамм

Press image to see more photos

Features:

Lifetime warranty since 2020

Japanese SANKO tubes (Crmo 4130)

no brake mounts

heat-treated head tube, BB, dropouts and down tube

inner gussets

gusset between seat stays

colors: matte mint, matt salmon, matt clear raw and matt black

size 20,5″; 20,8″; 21″;

rear end 12,9″;

standover 9,1″;

BB height 11,5″;

headtube angle 75,5º;

seattube angle 71º;

MID BB

weight 2300gr

The 12.9 chain stay is the modern middle ground. It suits any rider. With this chain stay, it is very easy to spin, and turn doing manuals, plus, your bunnyhops are still high.

We are fans of the underrated bottom brackets. In our opinion, this is the most underestimated frame feature. By lowering the BB, you bring your center of gravity closer to the bike’s center of gravity, and your bike becomes more intuitive. Plus, the load on the lower back is significantly reduced, which is also important.

Русский

Русский