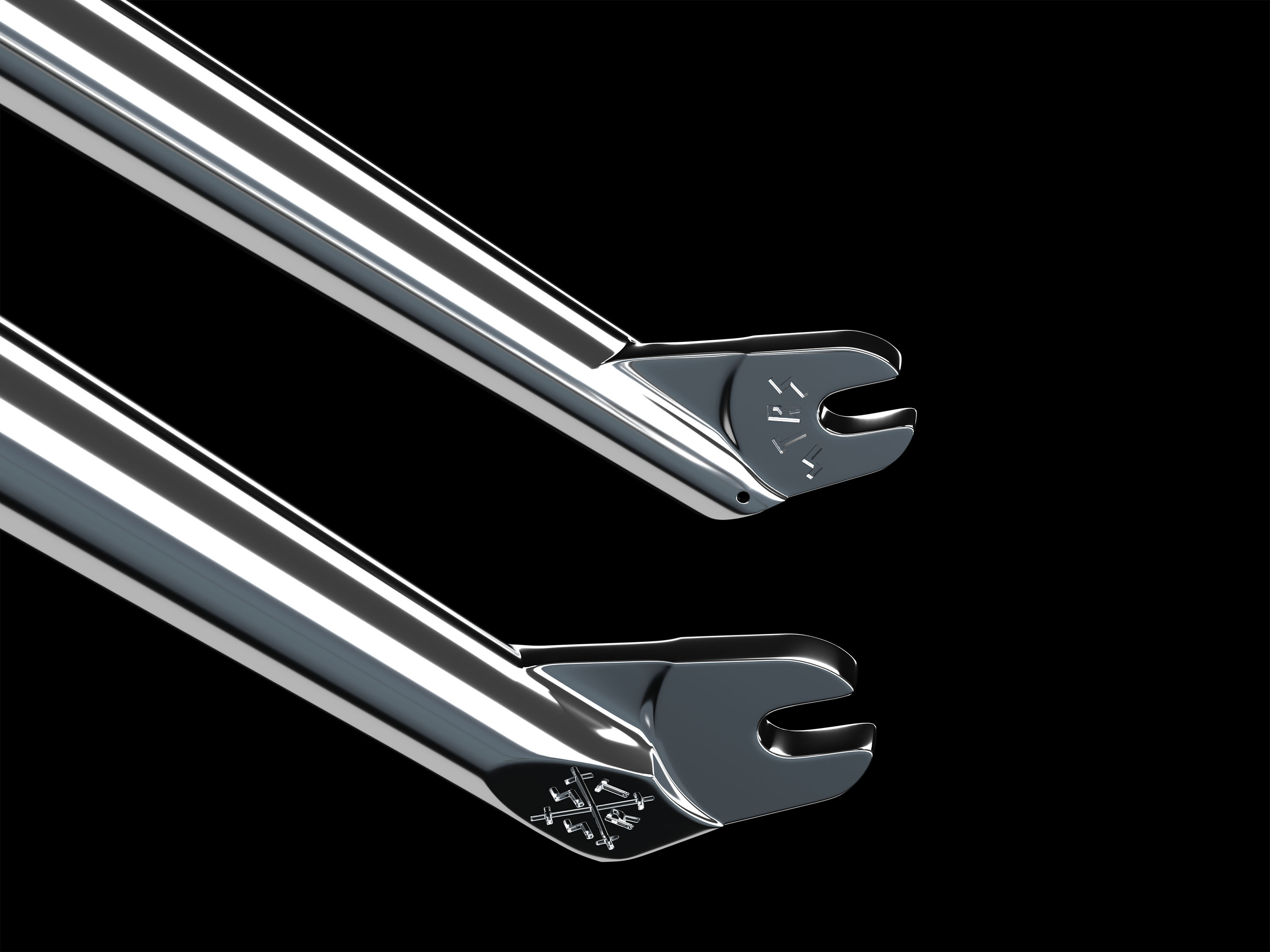

For the Voskhod fork, we specifically designed cast 8 mm dropouts from chromoly Japanese steel 4130. Casting not only made the fork more beautiful, but also allowed us to forget about the problem of dropouts being torn off during unsuccessful grinds.

With the collective decision of the STRS team, the classic offset was chosen to be 28 mm. In our opinion, it is optimal for the absolute majority of bike riders who cycle on the street and in the plazas.

For the Voskhod fork, we specifically designed cast 8 mm dropouts from chromoly Japanese steel 4130. Casting not only made the fork more beautiful, but also allowed us to forget about the problem of dropouts being torn off during unsuccessful grinds.

With the collective decision of the STRS team, the classic offset was chosen to be 28 mm. In our opinion, it is optimal for the absolute majority of bike riders who cycle on the street and in the plazas.

The attachment area of the legs with the steerer tube is one of the most high-loaded spots of the fork. To strengthen it, we first maximized the area of the seams where the legs are welded to the steerer tube. This is a simple and effective solution. But this was not enough for us, so we put an aluminum spacer on the bottom of the steerer tube. This spacer makes the steerer tube harder and it helps to redistribute part of the load on the legs. Thus, the load is spread across the fork and not concentrated at one point, which affects the strength.

There is not a single random detail in Voskhod fork. Most brands use a bolt with a thread diameter of 25mm. We reduced the bolt thread diameter to 24mm to make the steerer tube walls 30% thicker in the second most common place of breaking – the attachment point of the stem or the top headset bearing. By the way, we also thought about the convenience, the bolt at the Voskhod fork matches both 6mm and 8mm allen keys.

Press image to enlarge (specs are bellow)

There is not a single random detail in the Voskhod fork. Most brands use a bolt with a thread diameter of 25 mm. We reduced the bolt thread diameter to 24 mm to make the steerer tube walls 30% thicker in the second most breakable spot – the attachment point of the stem or the top headset bearing. By the way, we also thought about convenience, the Voskhod fork bolt matches both 6 mm and 8 mm Allen keys.

Specs:

heat-treated Japanese steel 4130

aluminum spacer in the steerer tube

variable thickness cast dropouts

offset 28 mm

steerer tube length 160 mm

topbolt for 6 mm and 8 mm Allen key

weight 1050 gr

Русский

Русский